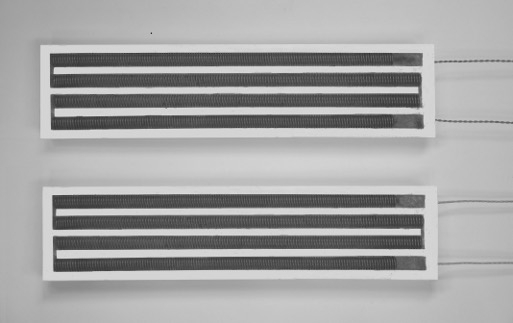

Embeded Coil Replacement Elements

Home > Products > HEATING ELEMENTS > Embeded Coil Replacement Elements

New high power density heating elements constructed with life-enhancing materials technology

Dual-refractory heating element system boosts power density while increasing operating life

- Rayteq’s newly designed heating elements feature maximum power density yielding the highest melting rates in the industry

- Improved materials technology combined with unique manufacturing processes virtually eliminates internal stresses while increasing strength and shock resistance

- Improved material properties reduce internal temperature of embedded heater coils for extended operating life

- Elements produced using highly automated equipment for higher quality and reduced risk of operator error

- No compromises with dual-refractory system—refractory with highest strength and best thermal properties selected for support panels; different refractory containing no harsh chemicals chosen for contact with heater coils

- Element coil surface is never subjected to corrosive chemical attack as with single-refractory elements. Result: Much longer operating life

- Since no paraffin or wax is used in coil embedding process there are no internal air gaps or hot spots to reduce coil life

- Stranded lead-to-coil welds have largest cross-sectional area in the industry by far, virtually eliminating weld failures

- Actual operating life up to 2 to 3 times longer than similarly appearing single-refractory elements

- Exact replacements featuring this new technology now available for Dynarad* and StrikoDynarad* furnaces in all sizes, wattages and voltages in both twisted and stranded leads

View Shopping Cart »

View Shopping Cart »